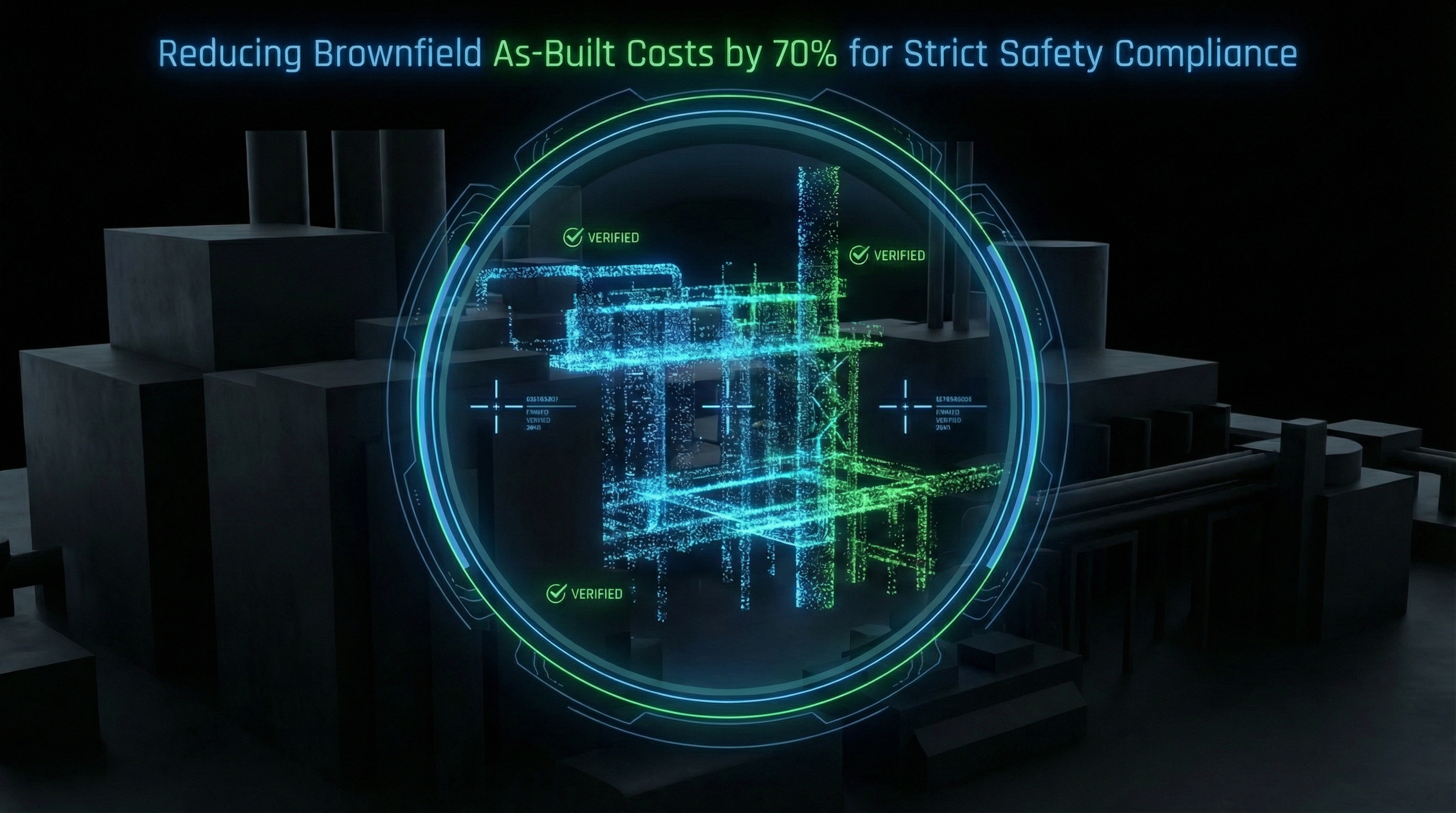

Reducing Brownfield As-Built Costs by 70% for Strict Safety Compliance

How a global fertilizer company achieved full HAZOP readiness and accurate As-Built P&IDs in just 12 weeks.

Introduction

In the high-stakes world of process industries, Safety and Compliance are non-negotiable. When a Global Fertilizer Company faced urgent regulatory requirements for a HAZOP (Hazard and Operability) update, they encountered a critical barrier common in Brownfield projects: the lack of accurate, up-to-date As-Built engineering documentation.

To ensure safe operations and meet strict regulatory standards for their 50,000 m² plant, the client didn't just need a 3D picture—they needed verifiable engineering truth.

In brownfield projects, the gap between "what's on paper" and "what's in the field" is a legal compliance risk.

The Challenge: The Risk of Inaccurate Data

Compliance Risk

Outdated drawings lead to incorrect risk assessments during HAZOP studies, failing to meet safety requirements.

Accuracy Gaps

Manual drafting is prone to human error, threatening the integrity of the As-Built data required for safety management.

The Solution: Precision-First "Integrated AI + Service Center"

1. The Triple-Check Protocol

To guarantee safety and compliance, our engineers implemented a rigorous validation process:

- Authenticity: Prioritizing Laser Scan Point Clouds for geometric detail.

- Consistency: Cross-validating 3D model spatial positions against Point Cloud.

- Resolution: Flagging inconsistencies between field data and existing records.

2. AI-Accelerated Efficiency

While accuracy was the goal, speed was the necessity. Our AI engine automated the extraction of over 80% of standard piping components and utilized OCR to bulk-extract Tag Numbers. This allowed experts to focus on complex verification rather than manual tracing.

Comprehensive Deliverables

Verified P&IDs

Synchronized multi-stage validation

AVEVA E3D Models

LOD300 detailed piping models

Regenerated ISOs

Derived directly from model

“Our triple-check strategy ensured that the digital model reflected reality. By strictly cross-referencing P&IDs with the Point Cloud, we provided the accurate data foundation essential for the plant's safety management.”

Conclusion

For Brownfield assets, accurate data is the foundation of safety. iModel3D eliminates the uncertainty of outdated drawings by providing precise, engineering-grade As-Built documentation.

Is your Brownfield documentation putting your compliance at risk?

Contact Us To Pilot Your ProjectSee how we deliver accuracy at 30% of the traditional cost.